Repair welding of aluminum, cast iron, cast steel, and various alloy metals with decades of experience.

Repair welding is a cost-effective alternative to new or used parts.

We use direct current (DC) and alternating current (AC) TIG welding at 350A, stick welding, metal powder spraying, flame soldering (oxygen/acetylene), and work with materials such as silver, brass, and aluminum.

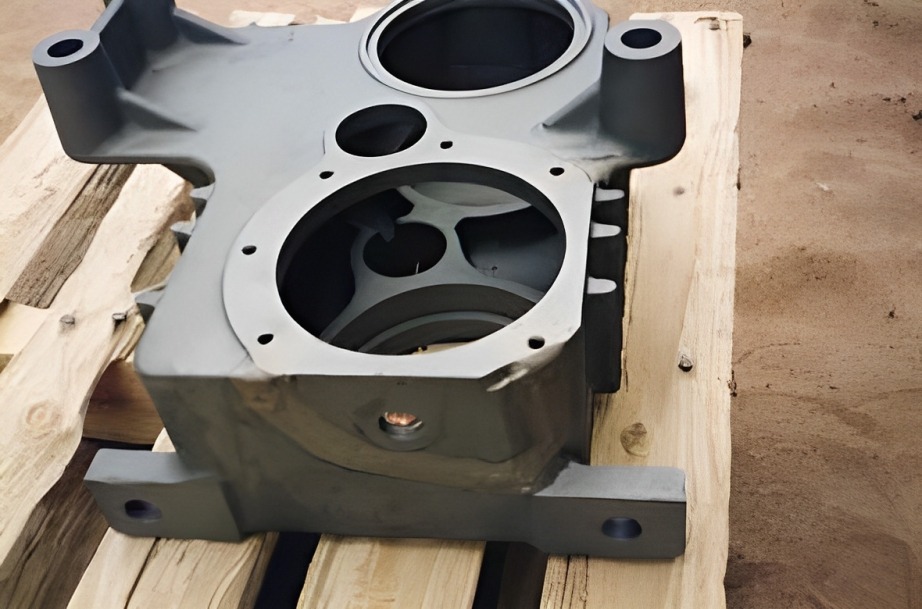

Examples of parts we repair include cylinder heads for cars, exhaust manifolds, oil pans, gearbox housings, air conditioning pipes, and aluminum or cast parts.

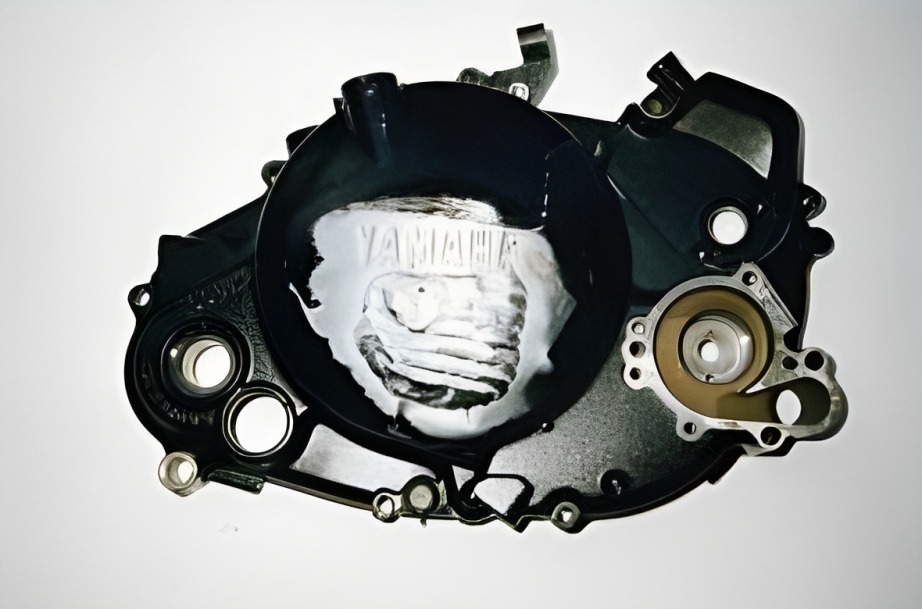

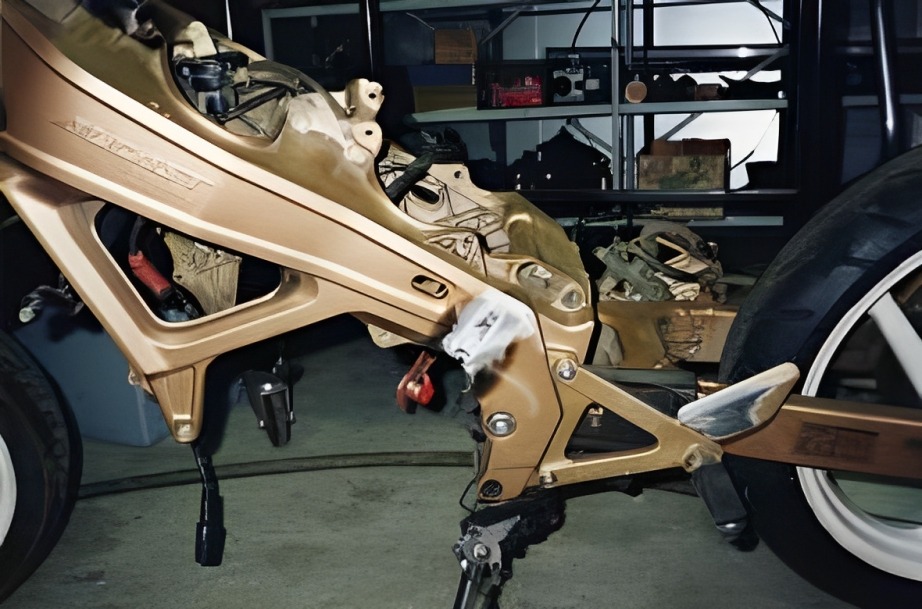

We also handle motorcycle cylinder block damage, engine blocks, rear forks, exhaust pipes, footpeg frames, tanks, and aluminum parts.

For tractors and machinery, we repair oil coolers, radiators, exhaust manifolds, and repair welding of aluminum, cast iron, and cast steel parts.

Truck intercoolers, intercooler pipes, aluminum bumpers, fuel tanks, exhaust manifolds, valve covers, and repair welding of aluminum, cast iron, and cast steel parts.

We also perform repair welding on all types of tools and small machinery parts.

In the repair of castings, preheating and post-weld heat treatment are crucial for successful welding. Preheating is done with a propane flame (oxy-propane), and the welding energy is applied along with propane, followed by cooling in refractory wool. Maximum cooling rate -100°C/h.

All parts subject to heat damage, such as seals, bearings, sensors, etc., must be removed from the vicinity of the welded part. Cleaning of oil and dirt is also essential. The so-called "empty block" is the best option for welding!