Repair of aluminum rims for passenger cars:

Straightening, turning, welding, and grinding work.

Repairing rims is a more economical option than replacing the entire set if one or more rims require repair. Often, manufacturers produce a rim model for a limited time, and the models change, making it difficult to find a replacement rim. The cost of acquiring a single rim can be high, so repairing a rare rim is a cost-effective solution, allowing you to keep the entire set in use.

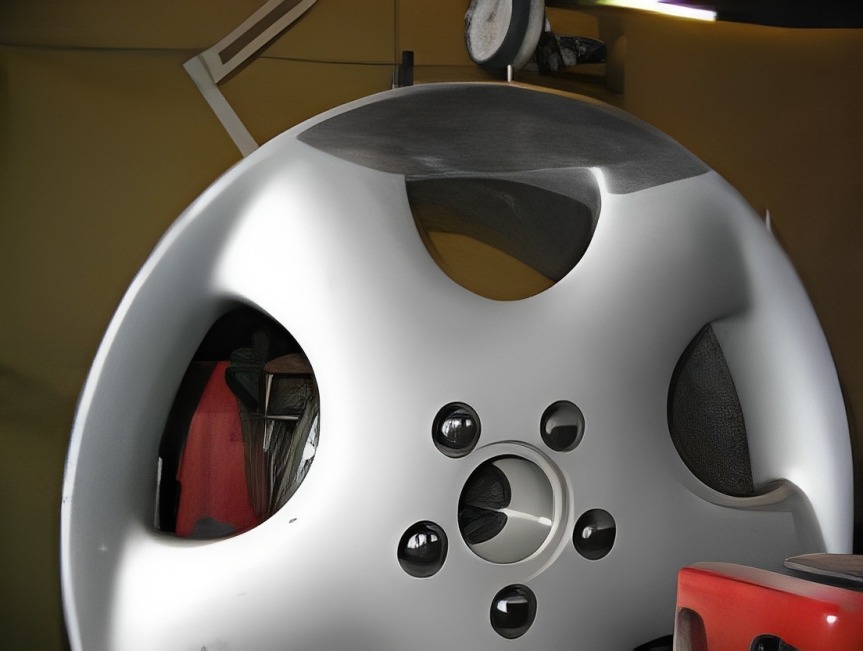

We use the K-MAK DORUK rim straightening machine. This electric hydraulic device is designed exclusively for this purpose. The rim is attached using its own mounting holes, ensuring a secure and precise fit to the straightening machine.

With hydraulic cylinders (5.6 tons of force per cylinder), we can correct edge bends, inner rim dents, and ovality. The allowable vertical runout tolerance is 0.1-0.4 mm from the centerline. For center runout correction, a special mounting kit is used, and the center mounting surface is turned down by 0.1-0.5 mm to correct runout. It is also possible to enlarge center holes and add center inserts.

We also perform repairs for edge wear and fractures, including welding, turning, and grinding. Note: the paint thickness can be up to 1.0 mm.

NOTE! The rims must be delivered without a tire!

1. REPAIRING AN OUTER RIM DENT

The edge of the slush punched through the rim.

Corrective punching and fracture welding.

Sanded and checked, ready for painting.

2. ULKOREUNAN MURTUMAN KORJAUS

Side slide to the edge of the cobblestone.

Welding filling and straightening of the inner edge.

Finishing sanding and straightness checking work.

3. SISäREUNAN PAINAUMAN KORJAUS

Inner edge depression, Drain cover below.

Straightening punching and hairline welding.

Finishing sanding and straightness checking work.

The damage shown in the example images is significant and has been selected for clarity. Repairs to inner and outer rim depressions often do not require welding and grinding. Tool marks from the straightening process are also minimal, reducing the need for repair painting.

The cost estimate depends on the nature and extent of the damage. A detailed description of the damage and a photo of the wheel make it easier to provide a cost estimate. Request a quote!

THERE IS NO WARRANTY FOR WELDING REPAIRS TO RIM CRACKS AND OTHER WELDING REPAIRS! THIRD-PARTY WELDED WHEELS ARE RECONDITIONED ONLY BY APPOINTMENT AND ARE INDIVIDUALLY PRICED. A MORE ACCURATE COST ESTIMATE WILL BE PROVIDED WHEN THE WHEELS ARE IN THE SHOP; IT IS DIFFICULT TO ASSESS WHETHER REPAIRING A WHEEL IS WORTHWHILE BASED SOLELY ON PICTURES.

For eBay, search for the wheel brand and "felgenbett" (outer rim). For example, "BBS Felgenbett."

Other search terms:

Measure the width of the old rim precisely if replacing only one space, e.g., due to damage. The width is measured from the attachment point (adhesive seam) to the outer edge. Also, count the number of rim bolts precisely; they vary between 30 and 36. RH wheels are measured in quarter-inch increments, so the dimensions of the rims are around 0.75" - 3.75".